Copper Pipe Fittings Cost Estimator

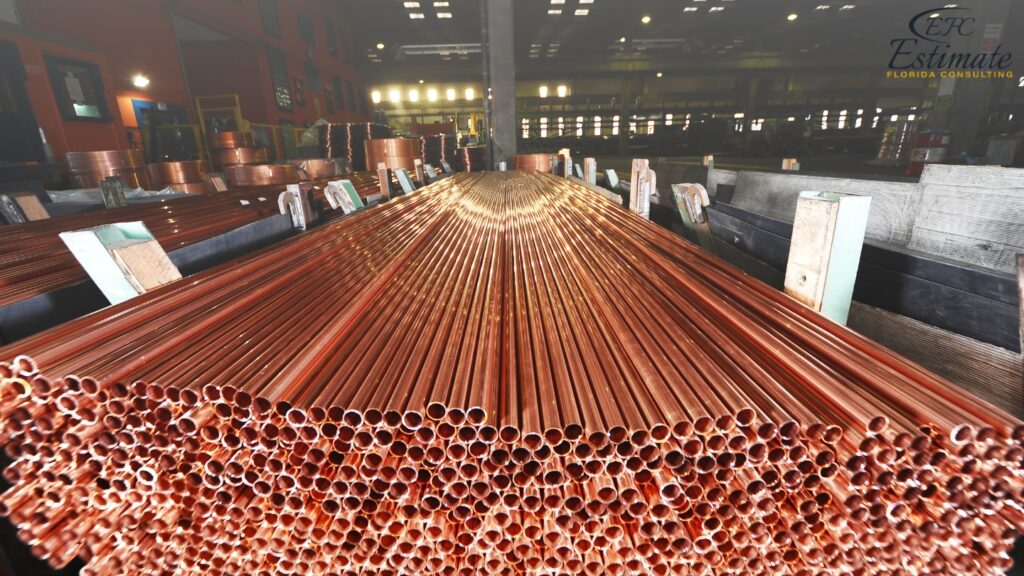

Copper pipe fittings are essential components in plumbing and HVAC systems, used to connect, control, and direct the flow of water, gas, or refrigerant within copper piping systems. Whether you’re working on a residential, commercial, or industrial project, understanding the costs involved in purchasing and installing copper pipe fittings is crucial for effective budgeting and planning. Estimate Florida Consulting provides expert cost estimator services to help you plan and execute your copper pipe fittings installation or replacement project with precision, ensuring that your project stays within budget while delivering reliable and efficient performance.

What Are Copper Pipe Fittings?

Copper pipe fittings are connectors used in plumbing and HVAC systems to join copper pipes together, change the direction of flow, or control the flow of liquids and gases. Common types of copper pipe fittings include elbows, tees, couplings, unions, and valves. These fittings are valued for their durability, corrosion resistance, and ability to withstand high temperatures and pressures. Estimate Florida Consulting provides estimate services that ensure your copper pipe fittings are carefully selected and installed, resulting in a reliable and efficient piping system tailored to your specific needs.

Copper Pipe Fittings Cost by Type

The cost of copper pipe fittings can vary depending on the type, size, and application. Each fitting type offers different levels of functionality and is used for specific purposes, which influences the overall price.

Copper Fitting Type | Price per Unit (Material Only) | Price per Unit (Installed) |

Elbows (90° and 45°) | $2.00 – $8.00 | $8.00 – $16.00 |

Couplings | $1.50 – $6.00 | $6.00 – $14.00 |

Tees | $3.00 – $10.00 | $10.00 – $18.00 |

Reducers | $2.50 – $8.00 | $8.00 – $16.00 |

Caps | $1.50 – $5.00 | $6.00 – $12.00 |

Unions | $4.00 – $12.00 | $12.00 – $24.00 |

Flanges | $5.00 – $15.00 | $15.00 – $30.00 |

Solder Ring Fittings | $3.50 – $10.00 | $10.00 – $18.00 |

Elbows (90° and 45°)

Elbows are used to change the direction of the pipe run. The cost of copper elbows typically ranges from $2.00 to $8.00 per unit for the material, with installation costs ranging from $8.00 to $16.00 per unit. Elbows are available in 90-degree and 45-degree angles and are essential for directing the flow of fluids around corners or obstacles.

Couplings

Couplings are used to connect two straight sections of pipe. The cost of copper couplings typically ranges from $1.50 to $6.00 per unit for the material, with installation costs ranging from $6.00 to $14.00 per unit. Couplings are simple yet crucial components in any piping system, allowing for seamless transitions between pipe sections.

Tees

Tee fittings allow for a branch in the piping system, directing the flow in multiple directions. The cost of copper tees typically ranges from $3.00 to $10.00 per unit for the material, with installation costs ranging from $10.00 to $18.00 per unit. Tees are commonly used in plumbing systems to split the flow into two separate lines.

Reducers

Reducers are used to connect pipes of different diameters, reducing the size of the flow path. The cost of copper reducers typically ranges from $2.50 to $8.00 per unit for the material, with installation costs ranging from $8.00 to $16.00 per unit. Reducers are essential when transitioning from a larger pipe to a smaller one, ensuring smooth flow without turbulence.

Caps

Caps are used to close off the end of a pipe, preventing flow. The cost of copper caps typically ranges from $1.50 to $5.00 per unit for the material, with installation costs ranging from $6.00 to $12.00 per unit. Caps are often used during repairs or system modifications to temporarily or permanently seal a pipe.

Unions

Unions allow for easy disconnection and reconnection of pipes, making them useful in systems that require frequent maintenance. The cost of copper unions typically ranges from $4.00 to $12.00 per unit for the material, with installation costs ranging from $12.00 to $24.00 per unit. Unions are particularly useful in HVAC systems and other applications where accessibility is important.

Flanges

Flanges are used to connect pipes to other components, such as valves or pumps, and are typically bolted together. The cost of copper flanges typically ranges from $5.00 to $15.00 per unit for the material, with installation costs ranging from $15.00 to $30.00 per unit. Flanges provide a secure and leak-proof connection and are often used in industrial applications.

Solder Ring Fittings

Solder ring fittings come with a pre-installed ring of solder, making installation easier and faster. The cost of solder ring fittings typically ranges from $3.50 to $10.00 per unit for the material, with installation costs ranging from $10.00 to $18.00 per unit. These fittings are ideal for applications where time efficiency and strong connections are crucial.

Copper Pipe Fittings Cost by Project Type

The cost of copper pipe fittings also depends on the specific project, such as whether you’re installing a new system, extending existing pipes, or replacing old fittings. Each project type presents unique challenges and costs that need to be considered.

Project Type | Cost Range |

New System Installation | $300 – $1,500 |

Fitting Replacement | $150 – $800 |

System Extension | $200 – $1,000 |

Custom Fabrication of Fittings | $500 – $2,000 |

Industrial Piping System Installation | $1,000 – $5,000 |

New System Installation

Installing a new copper piping system with all necessary fittings typically costs between $300 and $1,500, depending on the complexity of the system, the size of the piping, and the number of fittings required. New installations often require a variety of fittings, including elbows, tees, reducers, and couplings, to create a fully functional system.

Fitting Replacement

Replacing old or damaged copper pipe fittings typically costs between $150 and $800, depending on the number of fittings and the complexity of the replacement. Replacement projects are generally less expensive than new installations since the existing piping is already in place, but additional costs may arise if the old fittings have caused damage to the surrounding pipes or system components.

System Extension

Extending an existing copper piping system to accommodate new fixtures or reconfigure the layout typically costs between $200 and $1,000. This type of project involves adding new sections of pipe and the necessary fittings to integrate the extension seamlessly with the existing system. The cost will depend on the length of the extension, the types of fittings used, and any additional support or insulation required.

Custom Fabrication of Fittings

In some cases, custom-fabricated copper fittings may be required for specialized applications or unique system layouts. The cost of custom fabrication typically ranges from $500 to $2,000, depending on the complexity of the fittings and the level of customization required. Custom fittings are often used in industrial or high-end residential projects where standard fittings may not be suitable.

Industrial Piping System Installation

Installing copper piping in an industrial setting, where larger pipes and more robust fittings are required, typically costs between $1,000 and $5,000. Industrial installations often involve more complex layouts, higher pressures, and more stringent safety requirements, which can increase the cost of both the materials and labor.

Plumbing Guide

Duct Design & Installation

PEX Pipe Installation

Swimming Pool Plumbing

Additional Costs and Considerations

Several other factors can influence the total cost of your copper pipe fittings installation or replacement project. These include permits, inspection fees, and ongoing maintenance, all of which contribute to the overall cost and long-term performance of your piping system.

Additional Cost | Estimated Cost |

Permits and Inspection Fees | $100 – $500 |

Pipe Insulation (for Fittings) | $1.20 – $3.60 per Linear Foot |

Firestopping and Sealing | $50 – $300 per Project |

Annual Maintenance Plan | $150 – $400 per year |

Pressure Testing and Certification | $200 – $800 |

Permits and Inspection Fees

Depending on your location and the type of installation, you may need permits and inspections to ensure your copper piping system meets local building codes and safety standards. Permits and inspection fees typically range from $100 to $500. It’s important to work with a licensed contractor who understands local regulations and can handle the permitting process on your behalf. Ensuring compliance with local codes helps prevent potential fines, legal issues, and safety concerns.

Pipe Insulation (for Fittings)

Insulating copper pipe fittings can help prevent heat loss, reduce condensation, and improve energy efficiency. Insulation costs typically range from $1.20 to $3.60 per linear foot, depending on the type of insulation used and the length of the pipes and fittings being insulated. Insulation is especially important for fittings located in unconditioned spaces, such as basements, attics, or exterior walls.

Firestopping and Sealing

Proper firestopping and sealing are essential for preventing the spread of fire and ensuring that copper pipe fittings are safely installed through walls, floors, or ceilings. Firestopping and sealing costs typically range from $50 to $300 per project, depending on the complexity of the installation and the materials required. This process involves using fire-resistant materials to seal gaps around fittings and ensure that the system meets fire safety codes.

Annual Maintenance Plan

Regular maintenance is crucial for keeping your copper piping system and fittings in good working condition. An annual maintenance plan typically costs between $150 and $400 per year and includes services such as inspections, cleaning, and minor repairs. Investing in a maintenance plan helps extend the lifespan of your piping system and ensures that it continues to operate efficiently and safely.

Pressure Testing and Certification

After installation or repair, pressure testing and certification are often required to ensure that the system is leak-free and capable of handling the expected pressure. Pressure testing and certification typically cost between $200 and $800, depending on the size of the system and the testing requirements. This step is especially important in high-pressure or critical applications, such as in industrial or commercial settings.

Copper Pipe Fittings Costs by Project Scope and Application

Here’s a breakdown of estimated copper pipe fittings costs by application, providing you with a clear understanding of how different project types impact overall costs:

Application | Estimated Copper Fittings Cost per Fitting | Total Cost Range |

$2 – $20 | $100 – $2,000 (depending on quantity and complexity) | |

$5 – $30 | $500 – $10,000 (depending on quantity and complexity) | |

Industrial Piping System | $10 – $50 | $1,000 – $50,000 (depending on quantity and complexity) |

$5 – $30 | $500 – $5,000 (depending on quantity and complexity) |

Factors Influencing Copper Pipe Fittings Costs

The cost of copper pipe fittings can vary widely depending on several factors, including the type of fitting, the size, the quantity required, and additional expenses such as labor and installation. Understanding these factors will help you estimate the total cost of your project and make informed decisions that align with your budget.

Type of Copper Pipe Fittings

The type of copper pipe fitting you need is one of the most significant factors affecting the cost. Different fittings serve different purposes in a plumbing or HVAC system, and their prices can vary accordingly. The most common types of copper pipe fittings include elbows, tees, couplings, unions, and adapters.

Type of Copper Fitting | Average Cost per Fitting |

Elbows (45° and 90°) | $2 – $10 |

Tees | $3 – $12 |

Couplings | $1 – $8 |

Unions | $4 – $15 |

Adapters | $2 – $10 |

Elbows (45° and 90°)

Elbows are used to change the direction of the flow in a pipe. They are available in 45-degree and 90-degree angles and are commonly used in both plumbing and HVAC systems. The cost of copper elbows ranges from $2 to $10 per fitting, depending on the size and type of elbow.

Tees

Tees are used to split the flow of fluid into two separate directions, creating a “T” shape in the pipe. Tees are essential in systems where the flow needs to be divided or redirected. Copper tees typically cost between $3 and $12 per fitting, depending on the size.

Couplings

Couplings are used to connect two sections of pipe in a straight line. They are one of the most basic and commonly used fittings in plumbing and HVAC systems. Copper couplings are generally priced between $1 and $8 per fitting, depending on the size.

Unions

Unions are similar to couplings but are designed to be easily disconnected and reconnected, making them useful in systems that may require maintenance or disassembly. Copper unions typically cost between $4 and $15 per fitting, depending on the size and type.

Adapters

Adapters are used to connect pipes of different sizes or types, such as connecting a copper pipe to a threaded fitting. Copper adapters are priced between $2 and $10 per fitting, depending on the size and configuration.

Size of Fittings

The size of the copper pipe fittings also influences the cost. Larger fittings, which are required for larger diameter pipes, will generally be more expensive than smaller fittings. The size of the fitting you need depends on the size of the pipes in your system, as well as the specific requirements of your installation.

Fitting Size (Inches) | Cost Range |

1/2 inch | $1 – $5 |

3/4 inch | $2 – $8 |

1 inch | $3 – $12 |

1 1/4 inch | $4 – $15 |

1 1/2 inch | $5 – $20 |

2 inches | $8 – $30 |

As the size of the fitting increases, so does the cost. Larger fittings require more material and are often more complex to manufacture, which contributes to the higher price. It’s important to select the correct size for your system to ensure proper fit and function.

Download Template For Plumbing Project Breakdown

- Materials list updated to the zip code

- Fast delivery

- Data base of general contractors and sub-contractors

- Local estimators

Quantity Required

The quantity of copper pipe fittings you need for your project will also affect the overall cost. Purchasing fittings in bulk can sometimes result in discounts, reducing the cost per unit. If you’re working on a large project or need multiple fittings of the same type, it’s worth checking if bulk pricing is available.

Quantity | Cost Impact |

Single Fitting | Standard Price |

Bulk Purchase (10+ fittings) | 5% – 15% Discount |

Large Order (50+ fittings) | 10% – 20% Discount |

Purchasing in bulk can lead to significant savings, especially for large projects where many fittings are required. Be sure to compare prices from different suppliers and inquire about bulk discounts if you need a large number of fittings.

Labor Costs

Labor costs are another significant factor in the overall expense of installing copper pipe fittings. Professional installation by licensed plumbers or HVAC technicians is recommended for most projects, especially those involving complex systems or high-pressure applications. The cost of labor can vary depending on the complexity of the installation, the type of fittings used, and your location.

Installation Type | Average Labor Cost |

Professional Installation | $50 – $150 per hour |

DIY (Materials Only) | Varies (Not Recommended) |

Professional Installation

Hiring a licensed professional ensures that your copper pipe fittings are installed correctly and in compliance with local building codes. Professional labor typically costs between $50 and $150 per hour, depending on the complexity of the job and the region. Professionals have the tools and expertise needed to handle all aspects of the installation, from cutting and soldering pipes to securing fittings and ensuring a leak-free connection.

Adapters are used to connect pipes of different sizes or types, such as connecting a copper pipe to a threaded fitting. Copper adapters are priced between $2 and $10 per fitting, depending on the size and configuration.

DIY Installation

While some homeowners may consider DIY installation to save on labor costs, this is generally not recommended for copper pipe fittings due to the precision required for soldering and sealing connections. Improper installation can lead to leaks, which can cause water damage or reduce the efficiency of the system. If you do choose to install fittings yourself, it’s crucial to follow all safety guidelines and use the correct tools.

Additional Costs

In addition to the cost of the fittings themselves, there are additional expenses to consider when budgeting for copper pipe installation, including solder, flux, and tools.

Solder and Flux

Solder and flux are essential materials used to join copper fittings to pipes. Solder typically costs between $10 and $30 per roll, while flux is priced between $5 and $15 per container. The amount of solder and flux needed will depend on the number of fittings and the size of the pipes.

Tools

If you’re installing copper pipe fittings yourself, you’ll need specific tools, such as a pipe cutter, a torch, and pipe wrenches. The cost of these tools can range from $50 to $200, depending on the quality and brand. Investing in quality tools is important for ensuring a successful installation, especially if you plan to undertake additional plumbing or HVAC projects in the future.

Estimating the Total Cost

To provide a clearer understanding of what to expect, here’s an example of estimating the cost for a residential plumbing project that requires 20 copper pipe fittings, including labor, solder, and tools.

- Copper Pipe Fittings: $2 – $12 per fitting (20 fittings)

- Professional Installation: $50 – $150 per hour (3 hours)

- Solder and Flux: $15 – $45

- Tools: $50 – $150 (if not already owned)

Cost Component | Low Estimate | High Estimate |

Copper Pipe Fittings (20) | $40 | $240 |

Professional Labor (3 hours) | $150 | $450 |

Solder and Flux | $15 | $45 |

Tools | $50 | $150 |

Total Estimated Cost | $255 | $885 |

This example demonstrates how various components contribute to the overall cost of your copper pipe fitting installation project. By understanding these costs, you can better plan your budget and ensure that all aspects of the project are covered, leading to a successful and reliable plumbing or HVAC system installation. Proper planning also helps you avoid unexpected expenses, ensuring that your project stays within budget. The detailed breakdown provides transparency and allows you to see exactly where your money is being spent, helping you make informed decisions throughout the process.

Copper Pipe Fittings Cost Estimation

Accurate cost estimation is essential for the success of any copper pipe fittings installation or replacement project. It helps prevent unexpected expenses that could disrupt your budget and timeline, ensuring that your project stays on track from start to finish. Misestimating the number of fittings required, the type of material, or the complexity of the installation can lead to significant cost overruns and delays, which can negatively impact the overall success of the project. A precise estimate allows you to manage your resources more effectively, ensuring that the right materials and labor are available when needed. Estimate Florida Consulting provides accurate estimate services that deliver the precision needed to keep your project on budget and on schedule, ensuring that it meets the highest standards of quality and efficiency.

Copper Pipe Fittings Cost Calculator

To assist you in planning and budgeting your copper pipe fittings installation or replacement project more accurately, Estimate Florida Consulting provides estimate services that include a comprehensive cost calculator. This tool allows you to input specific details about your project, such as the type and number of fittings required, the total length of piping, and the complexity of the installation. The calculator then provides an estimated cost range tailored to your project’s specific needs, offering you a clear understanding of what to expect financially. This cost calculator is an invaluable resource that helps ensure your project plans align with your budget, allowing you to allocate the necessary financial resources effectively.

Why Choose Copper Pipe Fittings? Benefits for Durability and System Efficiency

Durability and Corrosion Resistance

Copper pipe fittings are known for their durability and resistance to corrosion, making them an ideal choice for plumbing and HVAC systems that require long-term reliability. Properly installed copper fittings ensure that your system can withstand the demands of daily use while maintaining optimal performance. Estimate Florida Consulting provides estimate services that help you select the best copper fittings for your needs, ensuring consistent durability and efficiency.

Efficient Flow and Connection

In addition to their durability, copper pipe fittings are designed to provide a secure and efficient connection between pipes, minimizing leaks and ensuring smooth flow throughout the system. High-quality copper fittings contribute to the overall efficiency of your plumbing or HVAC system, reducing energy consumption and maintenance costs. Estimate Florida Consulting provides estimate services that help you choose efficient copper fittings, allowing you to enjoy lower operational costs and improved system performance.

Long-Term Benefits of Investing in Quality Copper Pipe Fittings

Investing in quality copper pipe fittings offers numerous long-term benefits that can significantly impact the durability, reliability, and performance of your plumbing or HVAC system. By choosing high-quality fittings and ensuring proper installation, you can enjoy a reliable and cost-effective system that meets your needs for years to come.

Reduced Maintenance and Repair Costs

High-quality copper fittings reduce the likelihood of leaks, corrosion, and other issues that can lead to costly repairs. By minimizing the need for frequent maintenance and repairs, you can extend the lifespan of your plumbing or HVAC system and avoid unnecessary expenses. Regular inspections and timely maintenance can further enhance the longevity of your system, ensuring that it continues to operate efficiently for many years.

Enhanced System Performance

Properly installed copper fittings ensure that your plumbing or HVAC system operates at its best. This consistency in performance leads to better water flow, pressure, and temperature control, providing a more reliable and comfortable indoor environment. Whether it’s maintaining consistent water pressure in a residential plumbing system or ensuring efficient refrigerant flow in an HVAC system, high-quality copper fittings are essential for delivering reliable performance.

Environmental Benefits

Copper is a sustainable and recyclable material, making it an environmentally friendly choice for plumbing and HVAC systems. Investing in copper fittings not only provides long-term durability but also contributes to environmental sustainability. At the end of their service life, copper fittings can be recycled, reducing waste and conserving natural resources.

Get 5 New Leads Next 7Days With Our System

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- High-Rise Building

- Shopping Complex

Conclusion

Accurate cost estimation is the foundation of a successful copper pipe fittings installation or replacement project. Estimate Florida Consulting provides comprehensive and precise estimate services that help you plan and execute your project with confidence. By understanding the cost components and potential variables, you can make informed decisions that align with your budget and project goals. Contact us today to get started with your copper pipe fittings cost estimator services, and take the first step toward creating a durable, efficient, and cost-effective piping system. With our expert guidance and detailed cost breakdowns, you can be assured that your project will be completed on time, within budget, and to the highest standards of quality and performance. Our commitment to excellence ensures that every aspect of your project is handled with the utmost care and professionalism, resulting in a copper piping system that not only meets your needs but also enhances the overall reliability and efficiency of your property.

FAQs: Copper Pipe Fittings Cost Estimator

Copper pipe fittings are essential connectors used in plumbing and HVAC systems to join copper pipes, control the flow, and change directions. These fittings include elbows, tees, couplings, unions, and valves, known for their durability, corrosion resistance, and ability to withstand high temperatures and pressures.

The cost of copper pipe fittings varies based on the type and size. For example:

- Elbows (90° and 45°): $2.00 – $8.00 per unit (material only); $8.00 – $16.00 per unit (installed).

- Couplings: $1.50 – $6.00 per unit (material only); $6.00 – $14.00 per unit (installed).

- Tees: $3.00 – $10.00 per unit (material only); $10.00 – $18.00 per unit (installed).

Costs depend on the project type:

- New System Installation: $300 – $1,500

- Fitting Replacement: $150 – $800

- System Extension: $200 – $1,000

- Custom Fabrication of Fittings: $500 – $2,000

Additional costs may include:

- Permits and Inspection Fees: $100 – $500

- Pipe Insulation (for Fittings): $1.20 – $3.60 per linear foot

- Firestopping and Sealing: $50 – $300 per project

- Annual Maintenance Plan: $150 – $400 per year

- Pressure Testing and Certification: $200 – $800

Costs can vary based on application:

- Residential Plumbing System: $100 – $2,000 (depending on quantity and complexity)

- Commercial Plumbing System: $500 – $10,000 (depending on quantity and complexity)

- Industrial Piping System: $1,000 – $50,000 (depending on quantity and complexity)

- HVAC System Installation: $500 – $5,000 (depending on quantity and complexity)

Several factors influence the cost, including:

- Type of Fittings: Different fittings like elbows, tees, and couplings have varying costs.

- Size of Fittings: Larger fittings cost more due to more material usage.

- Quantity Required: Bulk purchases often come with discounts.

- Labor Costs: Professional installation costs $50 – $150 per hour, while DIY is not recommended due to the precision required.

- Additional Costs: Expenses for solder, flux, and tools add to the overall cost.

Investing in quality fittings offers long-term benefits such as:

- Durability and Corrosion Resistance: Ensures long-term reliability and performance.

- Efficient Flow and Connection: Reduces leaks and improves system efficiency.

- Reduced Maintenance and Repair Costs: Minimizes the need for frequent repairs.

- Environmental Benefits: Copper is sustainable and recyclable, contributing to environmental conservation.

You can estimate the total cost by considering the cost of fittings, labor, solder, flux, and tools. For example, a residential plumbing project requiring 20 fittings might cost between $255 and $885, depending on various factors.

Estimate Florida Consulting provides a comprehensive cost calculator that allows you to input details about your project, such as the type and number of fittings required, to get an estimated cost range tailored to your specific needs.

We Provide Copper Pipe Fittings Cost Estimator

Florida’s Cities

- Alachua

- Altamonte Springs

- Anna Maria

- Apalachicola

- Apopka

- Atlantic Beach

- Auburndale

- Aventura

- Avon Park

- Bal Harbour

- Bartow

- Bay Harbor Islands

- Boca Raton

- Bonita Springs

- Boynton Beach

- Bradenton

- Brooksville

- Cape Canaveral

- Cape Coral

- Casselberry

- Celebration

- Chipley

- Cinco Bayou

- Clearwater

- Clermont

- Clewiston

- Cocoa

- Cocoa Beach

- Coconut Creek

- Coral Gables

- Coral Springs

- Crystal River

- Dania Beach

- Davie

- Daytona Beach

- Deerfield Beach

- DeFuniak Springs

- DeLand

- Delray Beach

- Deltona

- Destin

- Dunedin

- Eagle Lake

- Edgewater

- Edgewood

- Eustis

- Fort Lauderdale

- Fort Meade

- Fort Myers

- Fort Myers Beach

- Fort Pierce

- Fort Walton Beach

- Fruitland Park

- Gainesville

- Greenacres

- Green Cove Springs

- Gulf Breeze

- Gulfport

- Haines City

- Hallandale Beach

- Hawthorne

- Hialeah

- Hialeah Gardens

- Highland Beach

- Hollywood

- Holly Hill

- Holmes Beach

- Homestead

- Hypoluxo

- Indialantic

- Jacksonville

- Juno Beach

- Jupiter

- Key Biscayne

- Key West

- Kissimmee

- LaBelle

- Lady Lake

- Lake Alfred

- Lakeland

- Lake Mary

- Lake Park

- Lake Wales

- Lake Worth

- Lantana

- Largo

- Lauderdale By The Sea

- Lauderhill

- Leesburg

- Lighthouse Point

- Longboat Key

- Longwood

- Maitland

- Marco Island

- Margate

- Melbourne

- Melbourne Beach

- Miami

- Miami Beach

- Milton

- Minneola

- Miramar

- Mount Dora

- Naples

- Neptune Beach

- New Port Richey

- New Smyrna Beach

- Niceville

- North Miami

- North Miami Beach

- North Port

- Oakland Park

- Ocala

- Ocean Ridge

- Ocoee

- Okeechobee

- Oldsmar

- Orange Park

- Orlando

- Ormond Beach

- Oviedo

- Palatka

- Palm Bay

- Palm Beach

- Palm Beach Gardens

- Palm Coast

- Palmetto

- Panama City

- Panama City Beach

- Pembroke Pines

- Pensacola

- Pinecrest

- Pinellas Park

- Plant City

- Plantation

- Pompano Beach

- Ponce Inlet

- Port Orange

- Port St. Lucie

- Punta Gorda

- Rockledge

- Royal Palm Beach

- St. Augustine

- St. Augustine Beach

- St. Cloud

- St. Pete Beach

- St. Petersburg

- Safety Harbor

- Sanford

- Sanibel

- Sarasota

- Satellite Beach

- Seaside

- Sebastian

- Sewall's Point

- Shalimar

- Stuart

- Surfside

- Tallahassee

- Tamarac

- Tampa

- Tarpon Springs

- Tavares

- Temple Terrace

- Titusville

- Treasure Island

- Valparaiso

- Venice

- Vero Beach

- Wellington

- West Melbourne

- West Palm Beach

- Weston

- Wilton Manors

- Winter Garden

- Winter Haven

- Winter Park

- Winter Springs

Google Reviews

Process To Get The Copper Pipe Fittings Cost Estimate Report

Here I am going to share some steps to get the copper pipe fitting cost estimate report.

-

You need to send your plan to us.

You can send us your plan on info@estimatorflorida.com

-

You receive a quote for your project.

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

-

Get Estimate Report

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.