Pipe Fittings (Elbow, Wye, Reducers, Tees, etc.) Cost Estimator

Pipe fittings such as elbows, wyes, reducers, and tees are essential components in plumbing and piping systems, allowing for changes in direction, size, and flow of the piping network. Whether you’re installing new pipe fittings or replacing existing ones in residential, commercial, or industrial settings, understanding the costs involved is crucial for effective budgeting and planning. Estimate Florida Consulting provides expert cost estimator services to help you plan and execute your pipe fittings installation or replacement project with precision, ensuring that your project stays within budget while meeting all performance and safety standards.

Factors Influencing Pipe Fittings Costs

The cost of pipe fittings can vary widely depending on several factors, including the type of fitting, material, size, installation complexity, and additional features like corrosion resistance or pressure ratings. Understanding these factors will help you estimate the total cost of your project accurately and make informed decisions that align with your budget and specific requirements.

Type of Pipe Fitting: Elbows, Wyes, Reducers, Tees, and More

The type of fitting you need is one of the most significant factors affecting the overall cost. Different fittings serve specific functions within a piping system, and each type has its own cost range based on its complexity and application.

Type of Pipe Fitting | Average Cost per Fitting (Material Only) |

Elbow (90° or 45°) | $2.40 – $12.00 |

Wye | $6.00 – $24.00 |

Reducer | $3.60 – $18.00 |

Tee | $4.80 – $24.00 |

Coupling | $1.20 – $9.60 |

Cap | $1.20 – $7.20 |

Union | $4.80 – $18.00 |

Flange | $7.20 – $36.00 |

Elbow (90° or 45°):

Elbows are among the most common types of pipe fittings used to change the direction of the flow within a piping system, typically by 90° or 45°. The cost of an elbow fitting ranges from $2.40 to $12.00, depending on the material and size. Elbows are essential for routing pipes around obstacles or connecting pipes at different angles, making them indispensable in both residential and industrial plumbing systems. The choice between a 90° or 45° elbow depends on the required direction change and the impact on flow dynamics; sharper turns like 90° elbows can create more turbulence, potentially affecting system efficiency.

Get Acquainted with Pipe Fittings

Wye:

Wye fittings are used to create branch lines in a piping system, allowing one pipe to connect with another at a 45° angle. The cost of a wye fitting typically ranges from $6.00 to $24.00. Wyes are commonly used in drainage systems to connect horizontal pipes to vertical stacks, ensuring smooth flow and reducing the risk of clogs or backups. They are particularly important in wastewater management systems where efficient and obstruction-free flow is critical to prevent blockages and maintain system performance.

Reducer:

Reducer fittings are used to connect pipes of different diameters, allowing for a smooth transition between sizes. The cost of a reducer fitting ranges from $3.60 to $18.00. Reducers are essential in systems where the flow rate or pressure needs to be adjusted by changing the pipe diameter, ensuring efficient and controlled fluid movement. For example, in a water supply system, reducers might be used to step down from a larger main supply line to smaller distribution lines, balancing flow rates and pressures to meet specific requirements.

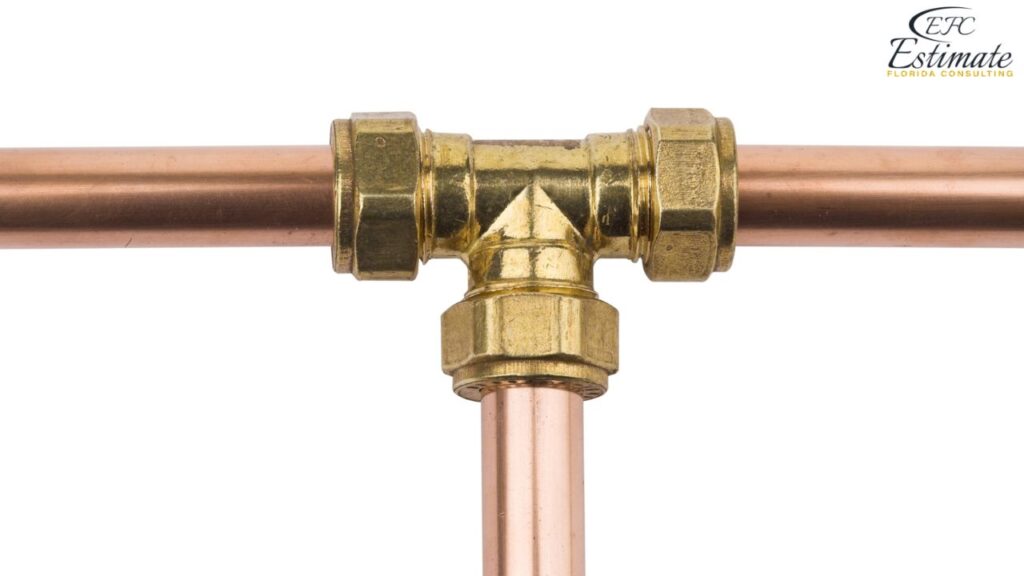

Tee:

Tee fittings are used to connect three pipes at a 90° angle, creating a T-shaped junction in the system. The cost of a tee fitting ranges from $4.80 to $24.00. Tees are commonly used in both supply and drainage systems to distribute or collect fluid from multiple lines, making them a versatile and essential fitting.

In complex piping networks, tees enable the distribution of fluids to various locations efficiently, ensuring that each branch receives the necessary flow and pressure to function effectively.

Coupling:

Couplings are used to connect two pipes of the same diameter in a straight line. The cost of a coupling fitting ranges from $1.20 to $9.60. Couplings are simple and straightforward fittings that are often used for joining pipes during repairs or extending a piping system. They are particularly useful in situations where sections of a pipe need to be replaced without disturbing the entire system, providing a reliable and easy-to-install solution.

Cap:

Cap fittings are used to close off the end of a pipe, preventing the flow of fluid or gas. The cost of a cap fitting ranges from $1.20 to $7.20. Caps are essential for sealing pipes during system testing, maintenance, or when a pipe is no longer needed. They provide a secure closure, ensuring that the system remains leak-proof and that any future modifications can be made easily by simply removing the cap.

Union:

Union fittings are similar to couplings but are designed to be easily disconnected and reconnected. The cost of a union fitting ranges from $4.80 to $18.00. Unions are commonly used in systems that require frequent disassembly for maintenance or inspection, providing a secure yet flexible connection. They are particularly valuable in systems where routine maintenance or adjustments are necessary, allowing for easy access without the need to cut pipes or disrupt the entire system.

Flange:

Flanges are used to connect pipes to other components, such as valves, pumps, or tanks, and are secured with bolts. The cost of a flange fitting ranges from $7.20 to $36.00. Flanges are often used in industrial applications where a strong, leak-proof connection is required, and where the system may need to be dismantled or modified. Flanges are also beneficial in applications that require precise alignment or where the connection must withstand high pressures and loads, making them a critical component in many industrial piping systems.

Material: Stainless Steel, Copper, Brass, PVC, or CPVC

The material of the fitting plays a significant role in determining the cost, durability, and suitability for different applications. Each material offers unique benefits and is selected based on the specific requirements of the piping system, including the type of fluid being transported, temperature, pressure, and environmental conditions.

Material | Average Cost per Fitting (Material Only) |

Stainless Steel | $6.00 – $36.00 |

$4.80 – $24.00 | |

Brass | $3.60 – $18.00 |

PVC | $1.20 – $12.00 |

CPVC | $2.40 – $18.00 |

Stainless Steel:

Stainless steel fittings are highly durable and resistant to corrosion, making them ideal for industrial and high-pressure applications. The cost of stainless steel fittings ranges from $6.00 to $36.00 per fitting. Stainless steel is often used in environments where hygiene is critical, such as in food processing or pharmaceuticals, as well as in corrosive environments like marine or chemical industries. The material’s ability to withstand extreme temperatures and aggressive chemicals without degrading makes it a top choice for critical applications where failure is not an option.

Copper:

Copper fittings are commonly used in plumbing systems for both hot and cold water supply due to their durability, heat resistance, and ease of installation. The cost of copper fittings ranges from $4.80 to $24.00 per fitting. Copper is a reliable and long-lasting material that is also resistant to corrosion and scaling, making it a preferred choice for many plumbing applications. In addition to its durability, copper has natural antimicrobial properties, which help maintain water quality and prevent the growth of bacteria within the pipes, contributing to a healthier plumbing system.

Brass:

Copper fittings are commonly used in plumbing systems for both hot and cold water supply due to their durability, heat resistance, and ease of installation. The cost of copper fittings ranges from $4.80 to $24.00 per fitting. Copper is a reliable and long-lasting material that is also resistant to corrosion and scaling, making it a preferred choice for many plumbing applications. In addition to its durability, copper has natural antimicrobial properties, which help maintain water quality and prevent the growth of bacteria within the pipes, contributing to a healthier plumbing system.

PVC:

PVC (Polyvinyl Chloride) fittings are lightweight, affordable, and resistant to corrosion, making them a popular choice for water supply and drainage systems. The cost of PVC fittings ranges from $1.20 to $12.00 per fitting. PVC is easy to work with and provides a cost-effective solution for many low-pressure and non-corrosive applications. Additionally, PVC fittings are widely available in various sizes and configurations, making them a versatile choice for a range of plumbing and piping projects.

CPVC:

CPVC (Chlorinated Polyvinyl Chloride) fittings are similar to PVC but can withstand higher temperatures, making them suitable for hot water systems. The cost of CPVC fittings ranges from $2.40 to $18.00 per fitting. CPVC offers a good balance of cost and performance, making it a common choice for residential and commercial hot water distribution. In addition to its temperature resistance, CPVC is also more resistant to chemical corrosion than standard PVC, making it a better choice for certain industrial applications where chemical exposure is a concern.

Size: Sizing for Your System

The size of the fitting will also affect the cost, with larger sizes generally being more expensive. The size of the fittings should be selected based on the diameter of the pipes and the flow requirements of your system.

Fitting Size (Diameter) | Cost Range per Fitting (Material Only) |

1/2 Inch | $2.40 – $12.00 |

3/4 Inch | $3.60 – $18.00 |

1 Inch | $4.80 – $24.00 |

2 Inches | $7.20 – $36.00 |

1/2 Inch:

Fittings with a 1/2-inch diameter are commonly used in residential plumbing systems for connecting smaller pipes that serve individual fixtures such as sinks, toilets, and showers. The cost for these fittings ranges from $2.40 to $12.00. This size is sufficient for handling the flow rates typically required in household plumbing systems, providing reliable connections at a cost-effective price.

3/4 Inch:

A 3/4-inch diameter fitting is typically used for larger residential or small commercial plumbing applications, such as main water supply lines or connections to water heaters. The cost for 3/4-inch fittings ranges from $3.60 to $18.00. This size provides a good balance between capacity and cost, ensuring adequate flow for multiple fixtures while maintaining system efficiency.

1 Inch:

One-inch diameter fittings are often used in commercial or industrial applications where higher flow rates and capacities are required. The cost for 1-inch fittings ranges from $4.80 to $24.00. These fittings are suitable for connecting larger pipes that serve multiple fixtures or high-demand applications, ensuring that the system can handle increased flow without compromising performance.

2 Inches:

Two-inch diameter fittings are used in larger commercial, industrial, or municipal systems, where significant volumes of fluid must be transported efficiently. The cost for these fittings ranges from $7.20 to $36.00. While more expensive, 2-inch fittings are essential for applications that require high flow rates and pressures, such as in fire suppression systems, large-scale water distribution networks, or industrial processing facilities.

Installation Complexity: Factors Affecting Labor Costs

The complexity of the installation can significantly impact the total cost of your pipe fittings project. Factors such as the layout of the piping system, accessibility, the need for specialized tools, and the material of the fittings all influence labor costs.

Installation Complexity | Average Labor Cost per Fitting |

Simple Installation | $1.20 – $6.00 |

Moderate Installation | $6.00 – $12.00 |

Complex Installation | $12.00 – $24.00 |

Simple Installation:

Simple installations involve straightforward setups, such as replacing old fittings with new ones of the same size and material in easily accessible locations. Labor costs for simple installations range from $1.20 to $6.00 per fitting. These installations are typically quick and cost-effective, requiring minimal tools and expertise. Simple installations are common in residential settings where the plumbing system is easily accessible and the fittings are not subject to extreme conditions or pressures.

Moderate Installation:

Moderate installations may involve more challenging work, such as installing fittings in confined spaces, upgrading pipe sizes, or switching to a different material. Labor costs for moderate installations range from $6.00 to $12.00 per fitting. This level of installation requires more time, expertise, and possibly additional tools, particularly if the new fittings need to be adapted to existing pipes or integrated into a more complex system. Moderate installations are common in commercial buildings or older homes where the plumbing system may require updates or modifications to meet current standards.

Complex Installation:

Complex installations involve significant challenges, such as installing fittings in hard-to-reach areas, dealing with high-pressure systems, or working in environments where precise alignment and sealing are critical. Labor costs for complex installations range from $12.00 to $24.00 per fitting. These projects require specialized tools, advanced skills, and careful planning to ensure that the fittings are installed correctly and the system operates safely and efficiently. Complex installations are often required in industrial settings or critical infrastructure projects where the stakes are high and the margin for error is low.

Estimating the Total Cost: A Detailed Example for a Residential Plumbing System

\

To provide a clearer understanding of what to expect, here’s an example of estimating the cost for installing pipe fittings in a residential plumbing system, including the fittings, materials, and labor.

- Elbows (90°, Copper, 3/4 Inch): $3.60 – $18.00 per fitting

- Tees (Copper, 3/4 Inch): $4.80 – $24.00 per fitting

- Reducers (Copper, 1 Inch to 3/4 Inch): $4.80 – $18.00 per fitting

- Labor (Moderate Installation): $6.00 – $12.00 per fitting

Fitting Type | Quantity | Low Estimate | High Estimate |

Elbows (90°, Copper, 3/4 Inch) | 10 | $36.00 | $180.00 |

Tees (Copper, 3/4 Inch) | 5 | $24.00 | $120.00 |

Reducers (Copper, 1″ to 3/4″) | 5 | $24.00 | $90.00 |

Labor (20 Fittings) | $120.00 | $240.00 | |

Total Estimated Cost | $204.00 | $630.00 |

This example demonstrates how various components contribute to the overall cost of your pipe fittings project. By understanding these costs, you can better plan your budget and ensure that all aspects of the project are covered, leading to a successful and efficient piping system. Proper planning also helps you avoid unexpected expenses, ensuring that your project stays within budget and is completed on time.

Additional Costs and Considerations

When installing or replacing pipe fittings, several additional factors can influence the overall cost of the project. These considerations should be factored into your budget to ensure that your plumbing system operates efficiently and effectively.

Additional Cost | Estimated Cost |

Labor Costs | $60 – $120 per hour |

Permit and Inspection Fees | $100 – $500 |

Transportation and Delivery Fees | $50 – $200 |

Tools and Equipment Rental | $30 – $150 per day |

Material Waste/Overage | 5% – 10% of total material cost |

Post-Installation Testing and Inspection | $100 – $300 |

Labor Costs:

The cost of labor for installing pipe fittings can vary widely depending on the complexity of the project, the type of fittings being installed, and the local market rates. Labor costs typically range from $60 to $120 per hour, with more complex installations requiring specialized skills and potentially higher rates. The total labor cost will depend on the time required to complete the installation, which can be influenced by factors such as the number of fittings, the material being used, and the accessibility of the installation site. In some cases, additional labor may be required for tasks such as cutting pipes, soldering connections, or making adjustments to the existing plumbing system.

Permit and Inspection Fees:

Depending on your location and the scope of your plumbing project, you may need to obtain permits and undergo inspections to ensure that the work complies with local building codes and safety standards. Permit and inspection fees typically range from $100 to $500, depending on the complexity of the project and the local regulations. While these fees add to the upfront cost, they are essential for ensuring that the installation is done correctly and meets all required standards. Failing to obtain the necessary permits or pass inspections can result in fines, delays, or additional costs for corrective work.

Transportation and Delivery Fees:

If you are purchasing large quantities of pipe fittings or heavy materials, you may incur transportation and delivery fees. These fees typically range from $50 to $200, depending on the distance from the supplier to the installation site and the weight or volume of the materials. Delivery fees can also vary based on the supplier’s policies, so it’s important to confirm these costs before placing an order. In some cases, it may be more cost-effective to pick up the materials yourself, especially for smaller projects, but this can require access to a suitable vehicle and the ability to safely transport the materials.

Tools and Equipment Rental:

Installing pipe fittings may require specialized tools and equipment, especially for materials like copper, which require soldering, or stainless steel, which may require threading or welding. Tools and equipment rental fees typically range from $30 to $150 per day, depending on the type of equipment needed and the duration of the rental. Common tools for pipe fitting installation include pipe cutters, wrenches, soldering torches, and threaders. Renting tools can be a cost-effective option if you don’t already own the necessary equipment, but it’s important to factor in the rental fees when budgeting for your project.

Material Waste/Overage:

When purchasing pipe fittings and other materials for your plumbing project, it’s important to account for material waste or overage. This typically amounts to 5% to 10% of the total material cost and covers any unexpected needs, such as additional fittings, cutting errors, or damage during installation. Ordering a little extra material ensures that you have enough on hand to complete the project without delays. It’s also a good idea to keep some extra fittings on hand for future repairs or modifications, especially if you are using materials that may be discontinued or difficult to find later.

Post-Installation Testing and Inspection:

After the installation of pipe fittings, it’s essential to test the system to ensure that all connections are secure and leak-free. Post-installation testing and inspection costs typically range from $100 to $300, depending on the complexity of the system and the testing methods used. Common testing procedures include pressure testing, which checks for leaks by applying air or water pressure to the system, and visual inspections to verify that all fittings are properly installed. Testing is a critical step in the installation process, as it helps identify and address any issues before the system is put into service. In some cases, you may also need to pass a formal inspection by a local building official, especially for projects that involve significant changes to the plumbing system.

Get 5 New Leads Next 7 Days With Our System

- Multi-Family House

- Single-Faimly House

- Modern House

- Duplex

- Ranch House

- Bungalow

Long-Term Benefits of Investing in Quality Pipe Fittings

Investing in high-quality pipe fittings offers numerous long-term benefits that can significantly impact the efficiency, performance, and longevity of your piping system. By choosing durable materials and ensuring proper installation, you can enjoy a reliable and cost-effective system that meets your needs for years to come.

Reduced Maintenance Costs:

High-quality pipe fittings are designed to withstand environmental challenges and require minimal maintenance, reducing the need for frequent repairs or replacements. This long-term reliability can lead to substantial cost savings over the life of the system, as fewer maintenance interventions are required, and the risk of costly failures is minimized. Reliable fittings also contribute to the overall stability and safety of the system, preventing leaks and breakdowns that could otherwise result in significant damage and expense.

Improved System Efficiency:

Efficient pipe fittings ensure consistent performance across your water supply, gas, or drainage system, preventing issues like blockages, leaks, or pressure drops. By investing in efficient materials and proper installation techniques, you can enhance the overall performance of your system, ensuring that it operates smoothly and effectively for years to come. Consistent performance is particularly important in systems where reliability is critical, such as in industrial processes, HVAC systems, or municipal water supply networks.

Enhanced Longevity:

Properly installed and maintained pipe fittings can last for decades, providing reliable service and protecting your investment. By choosing the right materials and installation methods, you can extend the lifespan of your piping system, ensuring that it continues to meet your needs without requiring costly replacements. The longevity of your fittings directly impacts the overall lifespan of the entire system, making it essential to invest in quality components that will stand the test of time.

Why Invest in Quality Pipe Fittings? Durability, Efficiency, and System Integrity

Investing in high-quality pipe fittings is paramount for maintaining the durability, efficiency, and overall integrity of your piping system. Fittings are often the most vulnerable points in any plumbing system because they are subject to the stresses of connecting pipes, changing flow directions, and withstanding pressure fluctuations. Poor-quality fittings can lead to leaks, system failures, and increased maintenance costs, resulting in higher expenses and potential downtime. By selecting the right materials and ensuring proper installation, you can protect your investment, minimize the risk of costly issues, and maintain a reliable and efficient piping system for years to come.

Durability:

Pipe fittings must endure the constant stress of pressure, temperature changes, and potential chemical exposure. The durability of these fittings directly impacts the longevity and reliability of the entire system. High-quality fittings made from materials like stainless steel, copper, brass, or durable plastics are designed to resist corrosion, withstand high pressures, and provide secure, long-lasting connections. Durable fittings reduce the likelihood of leaks, bursts, and other failures that can lead to significant damage and costly repairs. For example, in industrial settings where pipes carry chemicals or high-temperature fluids, using robust fittings is crucial to prevent accidents and maintain operational safety.

Efficiency:

Efficient pipe fittings play a critical role in maintaining optimal flow within a piping system. Properly sized and installed fittings ensure that fluids are directed accurately and efficiently, minimizing the risk of flow restrictions, turbulence, or pressure drops. This is particularly important in systems where maintaining consistent flow rates is essential for the system’s performance, such as in HVAC systems, industrial processes, or water supply networks. Efficient fittings also help conserve energy by reducing the work required by pumps and compressors, ultimately leading to lower operational costs. In complex systems with multiple branches and connections, choosing the right fittings can significantly enhance overall system efficiency and reliability.

System Integrity:

The integrity of your piping system hinges on the quality and reliability of the fittings used. High-quality fittings, when properly installed and maintained, help prevent leaks, system failures, and other issues that can compromise the entire system. Leaks in a piping system can lead to water damage, loss of pressure, and increased energy consumption, all of which can escalate operational costs and cause significant inconvenience. By investing in fittings that meet or exceed industry standards and regulations, you can ensure that your system operates safely and efficiently, minimizing the risk of costly repairs and downtime. In systems that transport hazardous materials or are critical to daily operations, maintaining system integrity through reliable fittings is essential for safety and performance.

Download Template For Pipe Fittings Project Breakdown

- Materials list updated to the zip code

- Fast delivery

- Data base of general contractors and sub-contractors

- Local estimators

Conclusion

Pipe fittings are the connectors that hold your entire piping system together, making them an essential component of any plumbing or infrastructure project. By understanding the various costs involved, including the type of fitting, material, size, installation complexity, and additional expenses such as labor and maintenance, you can plan your project effectively and ensure that all aspects are covered. The investment in high-quality pipe fittings, professional installation, and regular maintenance not only enhances the performance and longevity of your system but also provides long-term value that contributes to the success and sustainability of your infrastructure. Whether you are installing new pipe fittings or upgrading an existing system, this comprehensive guide will help you make informed decisions that align with your budget and performance expectations. Proper planning, attention to detail, and the use of quality materials will ensure that your pipe fittings project is a success, providing reliable service for years to come.

FAQs

Pipe fittings, such as elbows, wyes, reducers, and tees, are essential components in plumbing and piping systems. They allow for changes in direction, size, and flow within the piping network, ensuring the system functions effectively and meets the specific needs of the application.

The cost of pipe fittings can vary based on several factors, including the type of fitting, material, size, installation complexity, and additional features like corrosion resistance or pressure ratings. Understanding these factors helps in accurate budgeting and planning for your project.

Different types of fittings serve specific functions, and each comes with its own cost range:

- Elbow (90° or 45°): $2.40 – $12.00

- Wye: $6.00 – $24.00

- Reducer: $3.60 – $18.00

- Tee: $4.80 – $24.00

- Coupling: $1.20 – $9.60

- Cap: $1.20 – $7.20

- Union: $4.80 – $18.00

- Flange: $7.20 – $36.00

The material of the fitting is crucial in determining its cost, durability, and suitability for different applications:

- Stainless Steel: $6.00 – $36.00 per fitting

- Copper: $4.80 – $24.00 per fitting

- Brass: $3.60 – $18.00 per fitting

- PVC: $1.20 – $12.00 per fitting

- CPVC: $2.40 – $18.00 per fitting

Each material offers unique benefits, such as resistance to corrosion, heat, or chemicals, and is chosen based on the specific requirements of the piping system.

Larger fittings generally cost more due to the increased material and manufacturing complexity. Typical cost ranges by size are:

- 1/2 Inch: $2.40 – $12.00 per fitting

- 3/4 Inch: $3.60 – $18.00 per fitting

- 1 Inch: $4.80 – $24.00 per fitting

- 2 Inches: $7.20 – $36.00 per fitting

The size should match the diameter of the pipes in your system to ensure proper flow and performance.

Labor costs vary based on installation complexity, including the layout of the piping system, accessibility, and the need for specialized tools:

- Simple Installation: $1.20 – $6.00 per fitting

- Moderate Installation: $6.00 – $12.00 per fitting

- Complex Installation: $12.00 – $24.00 per fitting

The total labor cost will depend on the number of fittings and the specific challenges of the installation.

Additional costs may include labor, permit and inspection fees, transportation and delivery fees, tools and equipment rental, material waste, and post-installation testing:

- Labor Costs: $60 – $120 per hour

- Permit and Inspection Fees: $100 – $500

- Transportation and Delivery Fees: $50 – $200

- Tools and Equipment Rental: $30 – $150 per day

- Material Waste/Overage: 5% – 10% of total material cost

- Post-Installation Testing and Inspection: $100 – $300

These costs should be factored into your overall budget to ensure a successful project.

To estimate the total cost, consider the cost of the fittings, labor, and any additional expenses such as trenching, insulation, or corrosion protection. For example, installing 20 copper fittings (elbows, tees, reducers) in a residential plumbing system could cost between $204.00 and $630.00, depending on the complexity and labor involved.

Investing in high-quality pipe fittings ensures durability, efficiency, and system integrity. Quality fittings reduce the risk of leaks, system failures, and maintenance costs, providing long-term reliability and protecting your investment.

High-quality fittings offer reduced maintenance costs, improved system efficiency, and enhanced longevity. They help maintain optimal flow, prevent leaks and failures, and ensure that your piping system remains reliable and efficient for years to come.

Estimate Florida Consulting provides expert cost estimator services, helping you plan and execute your pipe fittings project with precision. We offer detailed cost estimates, guidance on material selection, and insights into installation complexity, ensuring that your project stays within budget and meets all performance standards.

System integrity is crucial for preventing leaks, maintaining pressure, and ensuring the overall performance of the piping system. High-quality fittings that are properly installed help preserve this integrity, minimizing the risk of costly repairs and system downtime.

Google Reviews

Process To Get Pipe Fittings Cost Estimate Report

Here I am going to share some steps to get pipe fittings cost estimate report.

-

You need to send your plan to us.

You can send us your plan on info@estimatorflorida.com

-

You receive a quote for your project.

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

-

Get Estimate Report

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.